Our EMPRA-FLOMAX BL series pumps are engineered to excel in abrasive environments, delivering superior performance and reliability. Designed with precision and durability in mind, these pumps are ideal for applications where abrasion resistance is paramount.

Whether it’s handling slurries, dewatering mines, or processing aggregates, our pumps ensure efficient operation and minimal downtime. With innovative features and robust construction, the EMPRA-FLOMAX BL series sets the standard for pump performance in challenging industrial settings.

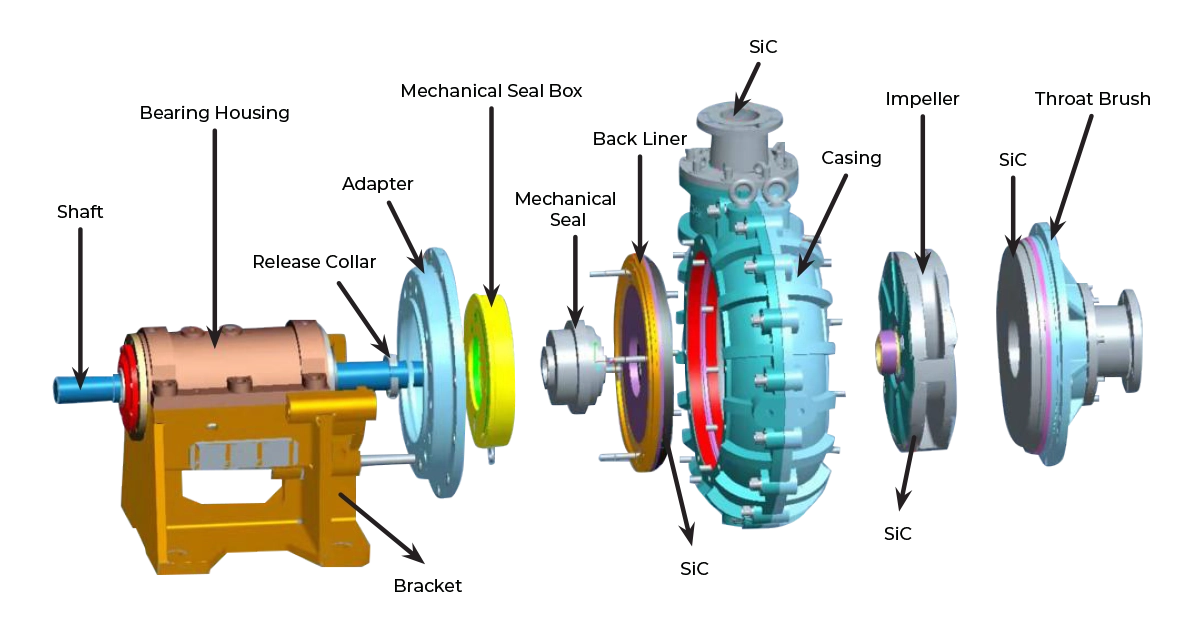

The EMPRA-FLOMAX BL Series of pumps has Silicon Carbide (SiC) wet parts and are designed for Slurry and tailings applications where high-wear rates, pump performance and costly downtime are a challenge to plant performance.

Why SiC?

- SiC is extremely wear-resistant and can outperform conventional steel/rubber parts by a factor of 4 to 6 times.

- Increased wear life and reduced downtime save costs

- High performance in aggressive PH levels

- Can handle top-size particles of 22mm as opposed to conventional alumina ceramic components, which are limited to approximately 6mm

- Higher impact resistance than ceramic alumina components.

EMPRA-FLOMAX BL Series of Slurry Pumps

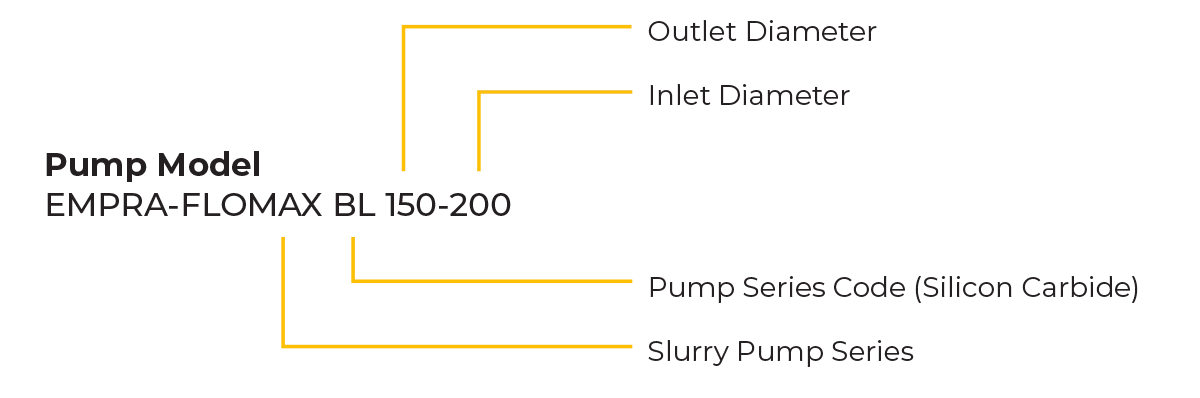

Model Designation Meaning

Pump Model: EMPRA-FLOMAX BL 150-200

EMPRA-FLOMAX BL

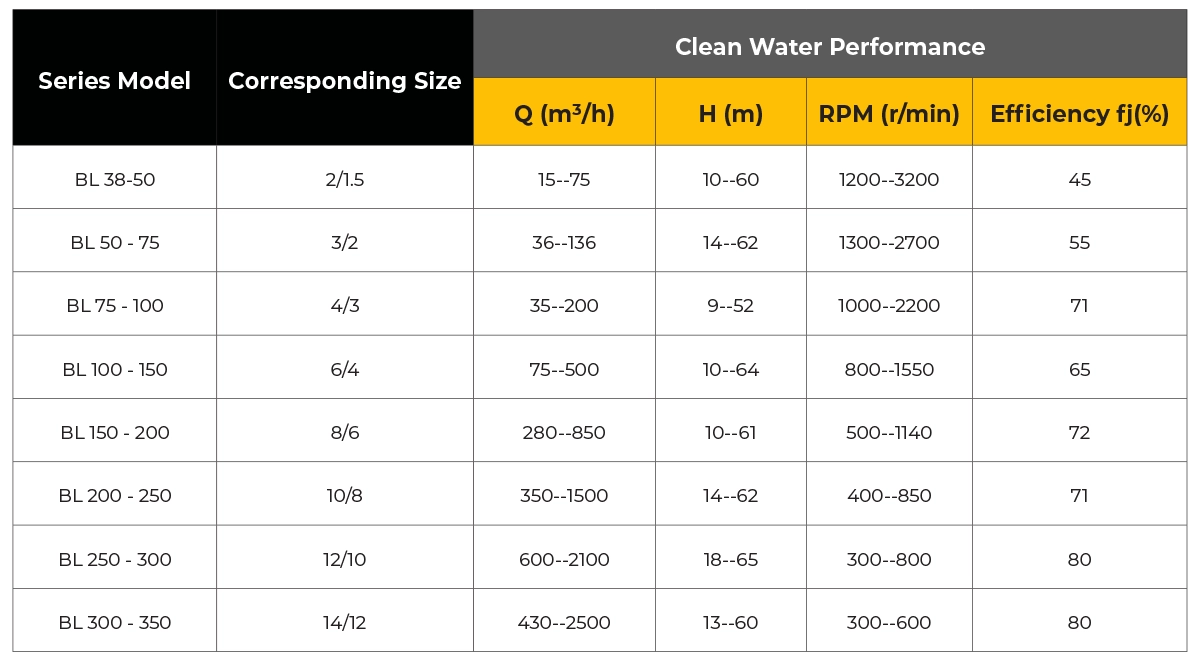

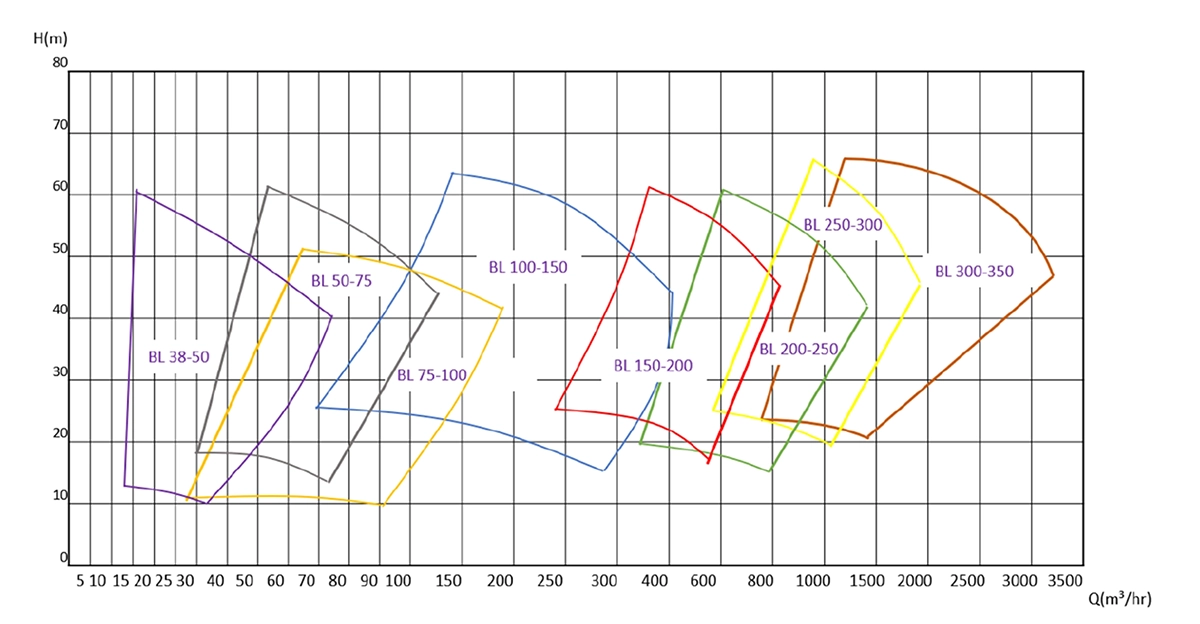

BL Range Slurry Pump Performance Curve Chart

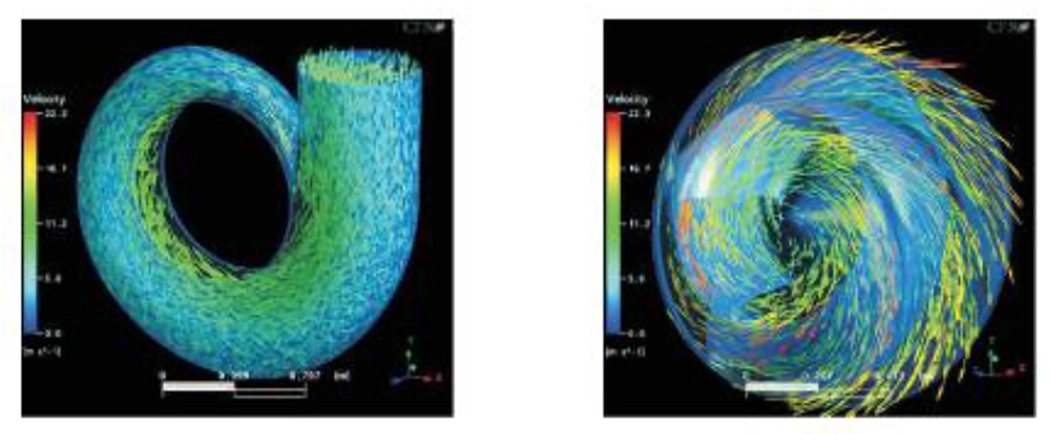

CFD Simulation for Volute & Impeller

The weight concentration of the slurry can be up to 75% for mine slurry and 45% for ash slurry.